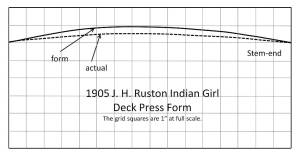

Jerry Stelmok Introduces This Fancy Old Canoe: A Comprehensive Guide To Restoring Antique Canoes

April 19, 2024

by Mike Elliott, Kettle River Canoes

The foreword to This Fancy Old Canoe is written by Jerry Stelmok. Here is his introduction to the book.

In this, Mike Elliott’s second book on canoe restoration, he uses his first book, This Old Canoe, which treats the more commonly encountered types of canoe damage and repair — broken and rotted ribs, planking, gunwales, need for recanvassing, and such — as a springboard to address some of the less common and often more challenging afflictions found in certain antique (and I’ll use Mike’s appropriate term) fancy canoes.

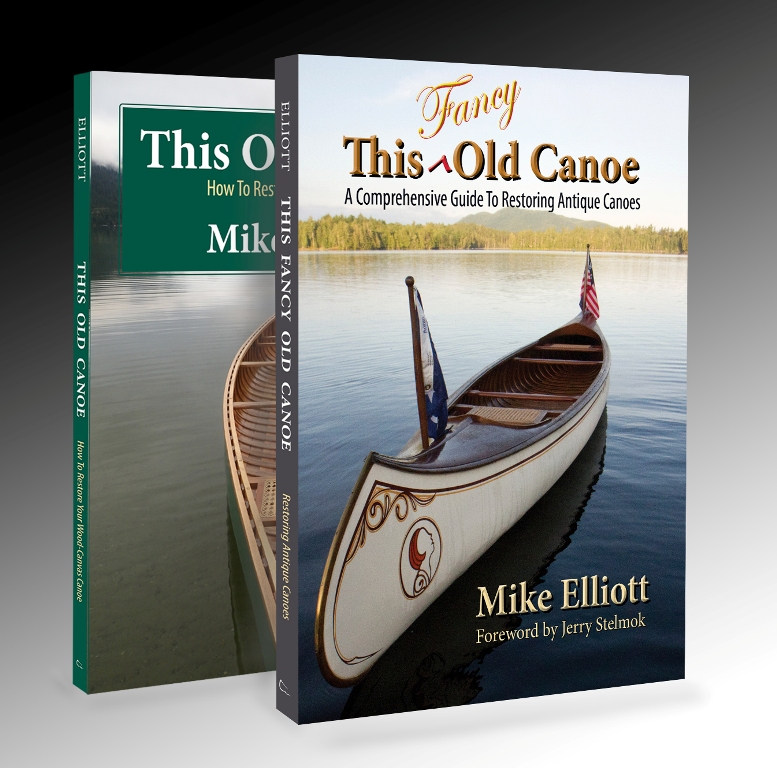

In the late nineteenth and early third of the twentieth centuries, recreational canoeing became very popular. Not just to explore the backcountry but as a social phenomenon giving rise to large-scale urban canoe clubs and liveries. On a Sunday afternoon on rivers such as the Charles in Boston, and the Detroit’s Belle Isle section, hundreds of canoes might be packed cheek by jowl ferrying sociable paddlers decked out in their finest outfits. These flotillas blossomed not only because they were fun and a chance to show off canoes, but also because they were one of the few acceptable activities where a fellow could be accompanied by his special girl unchaperoned — aside from the thousand or so other canoeists in proximity.

As an expression of this high-visibility exposure, the canoeing public began demanding finer, more strikingly adorned canoe models with more “flare.” Not merely fancy paint jobs, but higher, more romantic sheer lines, long decks leading to open cockpits with coamings, pennant holders, etc.

The builders responded. From the 1890s through the 1930s, with great skill and attention to detail, they employed extreme steam-bending of gunwales, stems and decks, to achieve the desired romantic flavor. Among these builders were Robertson, Brodbeck, and Arnold, in the Boston region. In Maine, they included Williams and Heckman in Kennebunk, Morris in Veazie, and Old Town in Old Town.

To make the canoes practically capsize proof, hollow air chambers termed sponsons were installed beneath the gunwales on some models.

All these extraordinary features present challenges that require innovative restoration procedures when they turn up as broken, dry rotted, or missing components in antique canoes to be repaired.

Mike breaks down these issues into various categories. With detailed instructions and clear photographs, he describes how to go about fixing the problems at hand.

It has been said that there’s more than one way to skin a cat. I’ve never skinned a cat, and never plan to. I like cats, although maybe not as much as I do dogs. The point is that, in my years of experience, I don’t necessarily employ the same techniques as Mike does for each task. Nor does the fellow down the road from me, Rollin Thurlow, who has been at canoe building/restoration as long as I have. He has also developed his own skills and methods. (But then, our town of Atkinson, Maine, is just possibly unique in that it has a full-time canoe shop for every 150 residents.) The late great Jack McGreivey of New York, considered by many of us to be the Dean of canoe restoration, had developed his own methods of tackling these challenges, too. Simply put, there is no single correct solution to address these often-complex issues. Mike freely points this out. His own methods are straight-forward and offer directions that, with care and some skill, should lead to success.

An important section of the book that I find very interesting is the restoration and repair of the various all-wood canoes manufactured in the Peterborough-Lakefield region of Ontario. Builders such as Herald and Stephenson, as early as the 1860s, made many types. These differ from the wood and canvas canoes in that their wooden hulls had to be perfectly watertight without a waterproof skin. I have very little knowledge about restoring such canoes, but I have always been impressed with their artisanship and the obvious challenges they present. Mike takes on a few of these himself and widens the book’s scope with excellent contributions from Sam Browning in the UK, who shares his experience restoring these impressive watercraft. Such is the value of the internet in all its forms when it is employed as it was initially intended — for sharing information.

Of course, numerous posts on the various apps and services these days offer advice. Some are excellent and some are sketchy. Some that are dependable are the Forums on the website of the Wooden Canoe Heritage Association (forums.wcha.org).

Still, when confronted with an exquisite courting canoe in need of major restoration; or just a more ordinary canoe that has issues with those unwieldy sponsons, you will find nothing quite as accessible and reassuring as a credible book on your bench. That is why This Fancy Old Canoe can be your best place to start.

Jerry Stelmok

Atkinson, Maine

Coming in July 2024: This Fancy Old Canoe: A Comprehensive Guide to Restoring Antique Canoes

April 8, 2024

by Mike Elliott, Kettle River Canoes

email: artisan@canoeshop.ca

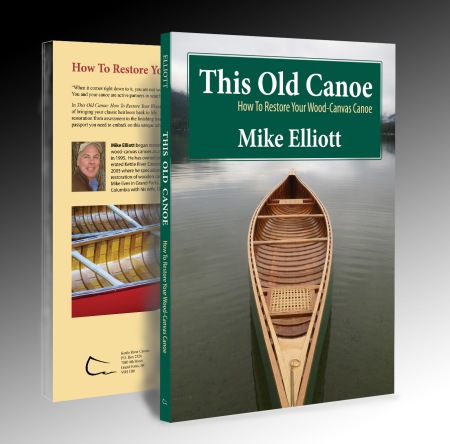

This Fancy Old Canoe: A Comprehensive Guide to Restoring Antique Canoes picks up where This Old Canoe: How to Restore Your Wood-Canvas Canoe left off. Whether you are an avid collector of antique canoes or you have limited woodworking experience and just want to get your family’s heirloom canoe back on the water, the two books work together to provide the techniques necessary to achieve success in your canoe-restoration adventure.

Repairing antique canoes can be a supreme challenge because their artisans built them with beauty and longevity in mind. Using over 400 photos and more than 100 plans and illustrations, This Fancy Old Canoe is designed to simplify the restoration process, guide you through it, and provide a measure of clarity to these complex tasks.

The book covers every aspect you may encounter in fancy old canoes, including:

- identifying your canoe and understanding its construction

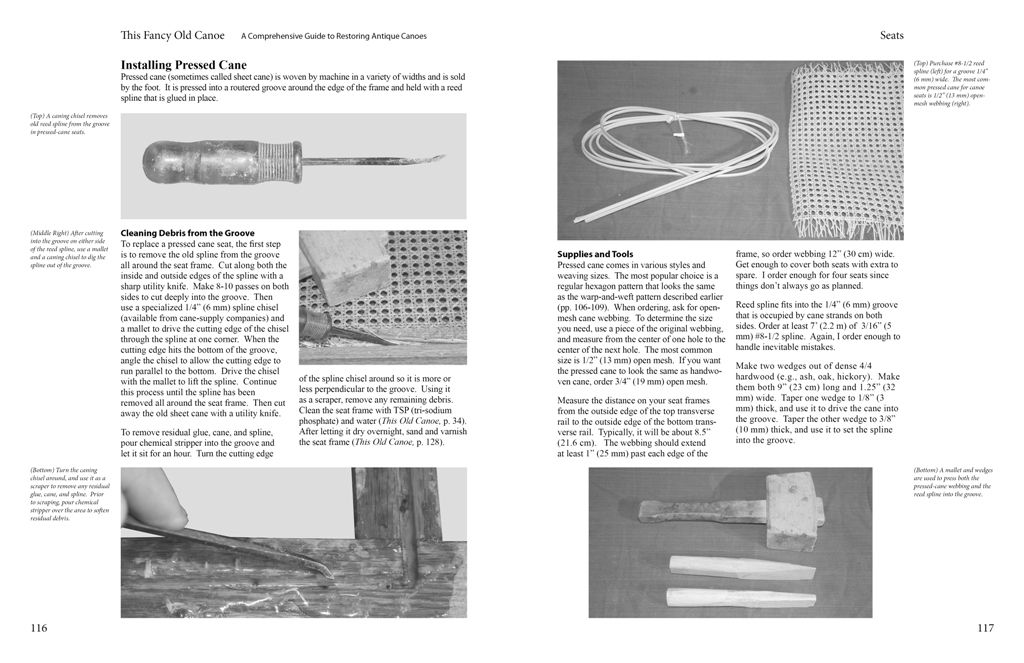

- replacing and weaving cane seats

- reverse engineering highly curved ends

- removing and installing pocketed inwales, wide outwales, and sponsons (air chambers attached to the sides of the canoe)

- repairing sailing rigs and floor systems

- applying fancy hand-painted designs

- sourcing materials

Many antique canoes, built in the Peterborough region of Ontario, Canada, are all-wood construction. They do not have a canvas cover. Instead, they rely on precise joinery to create a water-tight hull. This Fancy Old Canoe describes how to repair and replace every component in these elegant examples of floating art.

This Fancy Old Canoe: A Comprehensive Guide to Restoring Antique Canoes will be available in July 2024. Stay tuned.

A Brief Guide to Canvas-Covered Old Town Canoes

December 6, 2019

by Mike Elliott, Kettle River Canoes

email: artisan@canoeshop.ca

In America, the Old Town Canoe Company set the standard by which all other canvas-covered canoes are measured. With more than 170,000 produced over the course of seven decades or more, Old Town canoes are ubiquitous. So let’s look at a few of their classic models and compare them. From this, you ought to be able to identify your Old Town. However, be prepared for any American canoe to be called an Old Town.

The Old Town Canoe Company

The brand-name Old Town is synonymous with canvas-covered canoes in the United States. They are one of the only canoe companies to survive into the present day from their humble beginnings behind the Gray hardware store in Old Town, Maine in 1898. George and Samuel Gray incorporated the Old Town Canoe Company in 1901. They were entrepreneurs who hired others to design and build their canoes. The company kept meticulous build records which are still available through the WCHA. Their designs appealed to customers across the full range of styles from work-a-day canoes to elegant showpieces. So, let’s look at some of these quintessential canoes.

The Otca Model

Probably the best selling of all the Old Town models, the Otca was introduced in 1908 and began with a narrow hull (34.5” beam in the 16’ length) and later adopted the wide, flat-bottom of the Yankee model (36” beam in the 16’ length). According to their 1938 catalog, “The ‘Otca’ model is the widest, deepest and roomiest. These features make it the steadiest, safest and most capacious canoe we build. The floor is flat and wide, and carries far into the ends. The sides are convex, thus producing a handsome tumblehome. This model is not designed for speed but comfort, safety and fine appearance.”

The Otca caters to novice canoeists as well as those looking for a leisurely day on the water. There is little to no rocker at the ends, so it tracks very well. As a friend of mine explained, “It goes in a straight line. If you want to turn, just paddle until you reach the opposite side of the lake, get out, turn the canoe around and head back.”

It comes in 16’, 17’ and 18’ lengths and usually has a floor rack installed. It sports elegant, up-swept ends with a variety of deck styles over the years including a 16” solid-wood, pre-bent deck, a 20” one-piece deck with a low coaming and a 30” framed-veneer deck with a king-plank and coaming. The ribs in the Otca are standard-issue (5/16” thick, 2” wide spaced 1.5” apart and tapered on both sides to be approximately 1.5” wide at the sheer-line). The 16’ model weighs approximately 75 pounds.

The Yankee Model

This canoe (known as the Livery Model prior to 1920) was phased out in favour of the Otca in the 1940’s. It is a very easy paddling canoe. The flat bottom and soft chine makes it both steady and quick. It is 16’ long, 36” beam, 12” deep and weighs approximately 73 pounds. With fine entry lines and moderate rocker at the ends, it is a delight to paddle.

The Ideal Model

The Ideal comes in 16’ and 17’ lengths. It has a flat bottom, soft chine, straight sides, moderate rocker and fine entry lines making for a quick, responsive canoe. The floor is furnished with half-ribs to make it strong and comfortable. The ends sweep up with an elegant rise in the sheer-line. It is a quick, easy paddler and becomes more stable as it is loaded.

The Charles River Model

This canoe (introduced in 1903) is the same as the Ideal without the half-ribs. It was often furnished with a floor rack and was built with elegance and showy good looks in mind. That said, its flat-bottom, soft chine and fine entry lines produce in a canoe that was just as much fun to paddle as it was a delight to look at. Both the Ideal and Charles River were phased out in 1929.

The Guides Special Model

This is a slow, steady work-a-day canoe that comes in 18’ and 20’ lengths. The 18’ model has a 36” beam and is 13” deep. It has a flat-bottom, slight tumblehome, very little rocker and full ends. This workhorse is meant to be loaded and will get you where you want to go. Just don’t expect to get there quickly.

The H W Model

The Heavy Water Model is the consummate back-country traveler. It has moderate rocker, a semi-arch “yawl” hull, mild tumblehome through the entire length and full ends. With a narrow beam, this canoe is very quick on the water. Stability is traded for a canoe which is agile and responsive. It takes a little getting used to and once you do, it dances through river rapids. In my books, it is a delightful recreational canoe. The 16’ model has a 33” beam, is 12” deep at the centre and weighs about 70 pounds.

The 50-LB. Model

The “50-Pounder” is a series of light-weight versions of the HW model. They come in 11’, 13’ and 15’ lengths and weigh 50, 53 and 58 pounds respectively. They are constructed with ribs ¼” thick to produce canoes which are easy to portage. Modest tumblehome extends the entire length of the canoe and the bottom has a semi-arch and fine entry lines. The result is a versatile all-purpose canoe. Personally, I enjoy the 15’ model. It is light, quick and both steady and agile to handle rivers and lakes with ease.

How to Repair a Rib-and-Batten Canoe — Part 2

April 29, 2019

by Sam Browning

edited by Mike Elliott, Kettle River Canoes

email: artisan@canoeshop.ca

Note: In 2016, I put out a call for someone with a wide-board raised-batten canoe to bring it to my shop in British Columbia, Canada for me to restore and document as part of my second book ̶ “This Fancy Old Canoe”.

I was contacted immediately by Sam Browning. He was about to start restoring one of these canoes. He offered to take pictures of the project as he worked. I offered to come to his shop to see the canoe and meet him in person until he let me know he lived in Ely, Cambridgeshire, England.

A few months later, I received a USB flash drive in the mail from Sam. It contained 300 images and a copy of the posts he presented on the ‘Song of the Paddle’ web forum as he documented the restoration. For my blog (and eventually my book), I have edited Sam’s posts and added a few notes of my own (presented in italics). For this article, I am presenting the wide-board repairs.

Many thanks to Sam for his excellent work and generous contribution to my book.

*****************

My plank repairs consist of three boards that need to be replaced. There is a small piece missing from the bilge-plank at the stern. It starts at the last rib and runs to the internal stem. The second is a bilge-plank on the port side spanning across six ribs and the third is a long bilge-plank on the starboard side spanning across 17 ribs. My plan is to do the repairs in order from smallest to largest in order to learn on the small repairs and hone the process for the Big One.

Copper canoe nails (16-gauge 1″ or 25 mm long) are harder to get out than tacks on a cedar-canvas canoe as they are driven through a basswood (or Spanish cedar) plank as well as rock elm ribs before being bent over (dubbed) and clinched. The nails aren’t tapered either (apart from the point) and they hold well despite their age.

Getting rid of the heads and punching them through to the inside works best. I use an angle grinder set up with a 24-grit sanding disk to grind off the heads of the copper nails. Care must be taken to ensure that only the board to be removed is touched by the grinder.

For the first repair, I tidy up where the new piece of plank has to start, removing nails and chamfering the edge so that the new nails will go through both the new and existing wood.

The new plank is a piece of basswood cut carefully to its final dimensions and planed to match the thickness of the original boards (¼” or 6 mm). The end of the new plank butts up again the existing board and laps over it with a chamfered edge to match the chamfer on the existing board.

When I am happy with the fit, I drill pilot holes for the canoe nails at the join and push them through from the outside.

Next, whilst pushing them firmly from the outside, I bend (dub) the nails over with a clinching iron.

I wet the outside of the new plank with hot water so the nails sink into the wood without doing any damage.

Then, while holding a clinching iron on the bent nail inside, I hammer the outside until the nail is flush with the surface.

I repeat this along the top and bottom edge as well as two rows of nails in the stem. The end of the new plank extending past the stem is trimmed to complete the job.

I now turn my attention to the second plank repair. Because of what I’ve done already, I’m confident about the nailing procedure. For this repair, I have to learn to fit a plank that bends in two directions. In the factory, the planks would have been cut from patterns which (sadly) are not available to me. When the flat shape had been cut, the outside of the plank was soaked with boiling water poured over it. This swells the grain causing it to cup until the correct curve was reached. Then, it was nailed into place. My plan for the repair is to cut the plank oversize, hold it in place with a strap at each rib, then pour boiling water over it to cause it to curve. As it bends, I should be able to tighten the straps and hold it in place until it dries. I will then mark out the dimensions of the gap and work from there.

The first step is to fit basswood strips onto the outside surface of the exposed ribs. These spacers create a flush surface upon which to bent the oversized plank. To make spacers, I cut strips and poured boiling water over them. They bend into a suitable curve with very little pressure. I then tape the spacers into place.

I chamfer the edges of the old plank so the chamfer on the new plank fits precisely and allows a line of nails to go through both.

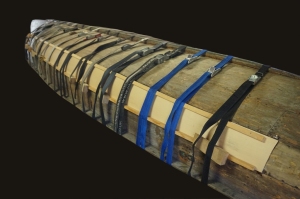

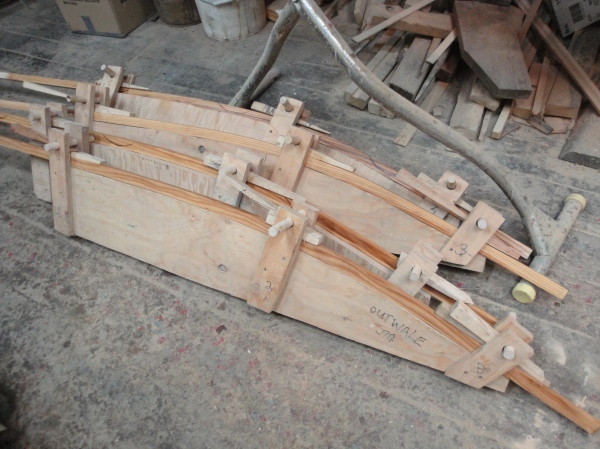

To spread the tension from the straps evenly along the new plank, I put battens along the both the top and bottom edges.

I use steam from a wallpaper stripper rather than pouring boiling water to help the plank curve into shape.

Two people would have made things easier, but after holding the steamer in place for a minute or so, then moving it along the plank and holding it with my knee, I am able to pull the straps progressively tighter. I work my way up and down the plank until it is tight against the hull along its full length. At both ends, I use ratchet straps and a couple of wedges to hold the curve tight to the hull. I allow the plank to dry for a couple of days.

Before I remove the straps, I clamp some blocks under the plank and at the ends. These act as reference points so I can put the plank back in exactly the same place while I mark, trim and fit the top edge.

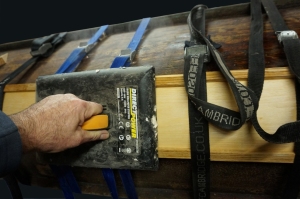

A planking gauge is used to mark the position of the gap’s edge even though the plank covers it and I can’t see.

The ‘L’ part of the gauge slides behind the plank and is moved along the edge of the gap while a pencil sits in the notch and draws a line.

Once the plank is marked, I use an apron plane to bring the plank dimension down to just outside the line. Then, a series of testing fitting, shaping, fitting, shaping until I have it just right. Then, the inside edges at the ends were chamfered to match the existing planks. The whole process takes about two hours before I am happy with it. I run a line of masking tape above and below the gap. On the tape, I mark where the ribs are so I can drill from the outside and place straps and blocks just to the sides of the ribs. This way, I can get the nails in, dubbed and clinched without worrying about the straps being in the way.

I nail the ribs, five in each, with a double row on the ends, then along the top and bottom edges into the battens – about 90 nails in all, drilled, pushed through, dubbed and clinched.

With the process honed, I turn to the Big One. I begin by making 16 basswood spacers for the ribs.

I steam and tape the spacers to the ribs.

I make two 12′ (3.7 meter) battens, arrange 16 straps and two ratchet straps. I make an oversized piece of basswood to fit over the gap. I steam the plank and tighten the straps, then steam and tighten again.

I check to make sure it is all tight with no gaps showing, then leave it for a couple of days.

The marking, cutting, fitting, shaping routine is the same as for the second plank.

The final fitting and nailing proceeds smoothly.

It’s great how once you have done a job, you wonder what all the fuss was about. I suppose, at any time, I could have pulled a strap too tight and split a plank. I could have planed too much off and left a gap. A plank could have split while I was nailing. If you need a plank for your board and batten canoe just let me know, I have a spare plank waiting in reserve.

The entire restoration process (including plank replacement) is described in my book – This Old Canoe: How To Restore Your Wood Canvas Canoe.

If you live in Canada, CLICK HERE to buy the book.

If you live in the USA, CLICK HERE to buy the book.

If you live in the UK, CLICK HERE to buy the book.

Si vous habitez en France, CLIQUEZ ICI acheter le livre.

If you have read the book, please post a review on Amazon, Goodreads and/or any other review site.

How to Repair a Rib-and-Batten Canoe — Part 1

April 29, 2019

by Sam Browning

edited by Mike Elliott, Kettle River Canoes

email: artisan@canoeshop.ca

Note: In 2016, I put out a call for someone with a wide-board raised-batten canoe to bring it to my shop in British Columbia, Canada for me to restore and document as part of my second book ̶ “This Fancy Old Canoe”.

I was contacted immediately by Sam Browning. He was about to start restoring one of these canoes. He offered to take pictures of the project as he worked. I offered to come to his shop to see the canoe and meet him in person until he let me know he lived in Ely, Cambridgeshire, England.

A few months later, I received a USB flash drive in the mail from Sam. It contained 300 images and a copy of the posts he presented on the ‘Song of the Paddle’ web forum as he documented the restoration. For my blog (and eventually my book), I have edited Sam’s posts and added a few notes of my own (presented in italics). For this article, I am presenting the rib repairs as well as some general history and description of the canoe.

Many thanks to Sam for his excellent work and generous contribution to my book.

*****************

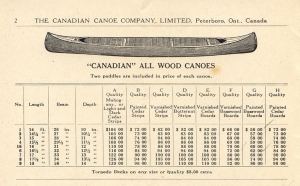

My canoe was made by the Canadian Canoe Company in Peterborough, Ontario. The company started in 1892. The last canoes of this type were built around the mid 1930’s. From the 1929 catalogue, my canoe is the 15′ 6″ No. 4 all wood canoe F quality (varnished, basswood boards). It has a 29½” (75 cm) beam and a depth of 11½” (29 cm) amidships. It is interesting to note that the garboards (the two planks on the bottom of the canoe) in my canoe are Spanish cedar ̶ a true mahogany.

This particular canoe was imported to England by Salter Bros. Ltd. of Oxford. Looking at the Salter Bros. history, they mention importing 21 canoes from Canada in 1930. My canoe may be one of those.

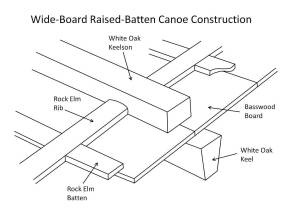

The exact origin of wide-board raised-batten canoe construction on a solid wood form is up for debate, but it was probably developed in a combined effort by Tom Gordon and John Stephenson in 1857. Construction began by laying down a white oak keelson. Rock elm ribs were then bent over the form and fitted into notches cut into the keelson. Wide basswood boards (three or four on each side) ran longitudinally and were attached to the ribs with copper canoe nails. Nail holes were pre-drilled and the nails were driven straight into the solid-wood form. The hull was then pulled free of the form and turned right-side up.

The nails were then ‘dubbed’ (bent over) to lie flat along the ribs (with the points towards the keelson) and then clinched tight with a clinching iron and cobblers hammer. The seams between the basswood boards were covered with ironwood battens between the ribs held in place with copper canoe nails.

If this was a cedar-canvas canoe with damaged ribs, I’d just take them out and replace them. With one of these canoes, you can’t do that without taking the whole thing apart. What I plan to do is bend new rib material which will extend from the keelson to the sheer-line and nail it in place alongside the existing rib (this process is commonly used in wooden boat repair and is known as sistering ribs).

Because the canoe has had broken ribs for many years, it needs a bit of reshaping before I can bend and install the new rib material. Straps around the canoe with a couple of lengths of timber to push in the right places helps to reshape.

I bend the new rib material inside (straight-grained english oak cut to size and shaped to replicate the original before it is soaked overnight and steamed for an hour), on top of the old rib. Any spring-back should result in the right size and curve. The end of the new rib at the keelson is held in place by a scrap piece of hardwood wedged between it and a length of timber positioned above the keelson and clamped on top of the thwarts. The rest of the new rib is held in place with g-clamps (c-clamps) and spring clamps. This process is facilitated by the fact that one of the basswood planks is missing. The missing plank allows me to use a couple of spring clamps to hold it in the middle.

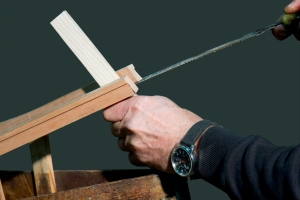

Once the new rib has dried overnight, I decided to cut the battens first as it has to be easier than removing them and installing new ones. With over ten copper nails dubbed and clinched in each batten, it would be impossible to remove them in one piece, and they do have to fit exactly. I cut the battens with an inlay saw (3″ or 76 mm blade with 20 teeth per inch and a 0.011″ or 0.3 mm kerf). Its curved blade allows me to remove a small piece of the batten with less chance of damaging the planks.

The battens are carefully marked and cut. I have to make sure the plank is clean where the new rib will go. I clamp the rib in position making sure it fits well against the keelson and the original rib.

When the new rib is in place, I drill a pilot hole through the rib and plank at the centre of each rib. Then, I push a 19 mm (¾”) copper canoe nail in from the outside. The nail is then dubbed towards the keelson and clinched tight. Then, I pilot, dub and clinch three more nails into each plank as well as one at each batten. I cut the rib flush with the sheer-line and shape the rib-top to match the existing ribs.

At the gap, where the broken rib is exposed, I cut it off in line with the battens.

In some sections, retention of the original hull shape was facilitated by clamping a hardwood batten on the outside of the exposed original ribs.

The broken sections of original rib were cut away with the inlay saw as well as the sections of batten required to allow for positioning of the new rib which was then soaked, steamed and clamped in place.

A total of twelve broken ribs were sistered in this canoe. The ribs were repaired in stages, doing every second rib along the length of the canoe in order to maintain the shape of the hull as much as possible.

The entire restoration process (including rib repairs and replacement) is described in my book – This Old Canoe: How To Restore Your Wood Canvas Canoe.

If you live in Canada, CLICK HERE to buy the book.

If you live in the USA, CLICK HERE to buy the book.

If you live in the UK, CLICK HERE to buy the book.

Si vous habitez en France, CLIQUEZ ICI acheter le livre.

If you have read the book, please post a review on Amazon, Goodreads and/or any other review site.

by Mike Elliott, Kettle River Canoes

email: artisan@canoeshop.ca

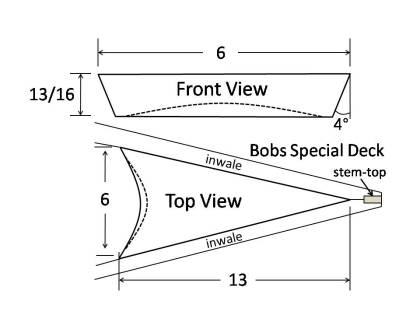

The blogs I do on the specifications of canoe components for various types of canvas-covered canoes seem to be quite popular. Apparently, I am the only one out there taking the time to write about this stuff and share it with others on-line. This time around, I am presenting a restorer’s guide to the Bobs Special from the Chestnut Canoe Company.

This canoe was one of two lightweight pleasure canoes built by Chestnut (the other was an 11’ solo canoe called the Featherweight that weighed about 38 pounds). Before I talk about the canoe, I’d like to clarify the name. According to Roger MacGregor in his book When the Chestnut was in Flower, Henry and William Chestnut were real history buffs. The telegraph code for the 15’ 50-Lb. Special was BOBS and made reference to Lord Roberts, a major figure during the Second Boer War in South Africa. Over the years, as this wide, light-weight canoe became more difficult to keep under the weight limit of 50 lbs. (the average weight was 58 pounds while the carrying capacity was 700 pounds), they changed the name. I have seen a variety of Chestnut catalogues call it Bob’s Special, Bob Special and Bobs Special. So, feel free to take your pick.

If you happen to have a Bobs or have been lucky enough to come across one in need of some TLC, you will notice what a sweet little canoe this is. It paddles like a dream which is surprising for a canoe that is 37” (94 cm) wide. Its bottom has a shallow-arch that reduces the waterline width when paddled with a light load. There is a fair amount of rocker in the ends which adds to its maneuverability. At the same time, it is not difficult to stand up in a Bobs – making it ideal for fly-fishing or general recreational paddling for a less experienced paddler.

One little note here: I am listing all of the dimensions in inches. I apologize to all of you who are working in metric. The canoes were built with imperial measurements originally, so I find it easier and more accurate to stick with this measurement scale.

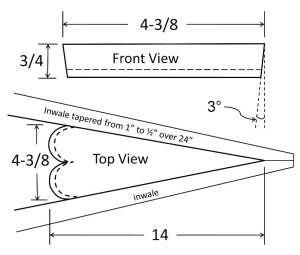

Inwales –The inwale is a length of White Ash or Douglas Fir 15/16” high with the edge grain visible on the top surface. It is fashioned to fit the tumblehome present on most Chestnut canoes. Therefore, the top surface is 9/16” wide while the bottom width is 11/16”. The last 18” or so at each end is tapered down to about ½” wide (top and bottom) along the sides of the decks. All of the transverse components (centre thwart and seats) are attached to the inwales with 10-24 (3/16”) galvanized steel carriage bolts. I replace these with 10-24 silicon-bronze carriage bolts.

The gunwales (both inwales and outwales) are pre-bent about 18” from the ends. If you are replacing these components, the wood will have to be soaked for 3 days, heated by pouring boiling water over them and bent onto custom-built forms in order to get a proper fit.

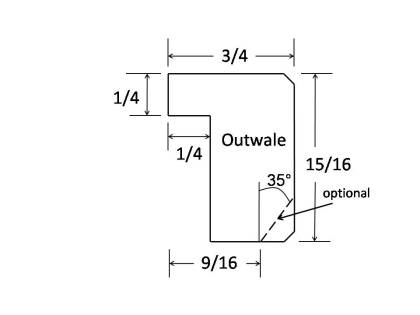

Outwales – The outwales are also made of White Ash or Douglas Fir. Depending on when the canoe was built, the outwales may have a chamfered edge on the bottom of the outside surface. Water often gets trapped under the outwales and results in rot on the inside surface of the originals because they assembled the canoe first and then applied paint and varnish. Consequently, the inside surfaces of the outwales are bare wood. Therefore, I usually end up replacing this component. Prior to installation, I seal the wood on all surfaces with a couple of coats of spar varnish. Unlike the original builders, I do all of the painting and varnishing first and then assemble the canoe.

Decks – The decks the Bobs Special were made of hardwood – usually maple, white ash or white oak. Sometimes, they used mahogany to help reduce the overall weight. By the time you start restoring your canoe, the decks are often rotted along with the stem-tops and inwale-ends. They are attached to the inwales with six 1¾” #8 bronze wood screws. As with the outwales, I help prevent future rot by sealing the decks on all surfaces with a couple of coats of spar varnish. The deck extends about 18” into the canoe from the end.

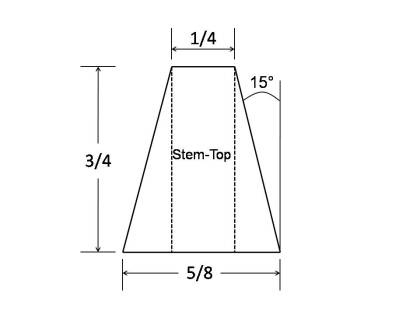

Stem-Top – You will rarely if ever have to replace the entire stem. However, I rarely see an original stem-top that is not partially or completely rotted away. Because the top 6” or so of the stem is straight, you can usually make the repair without having to pre-bend the wood to fit the original stem-profile.

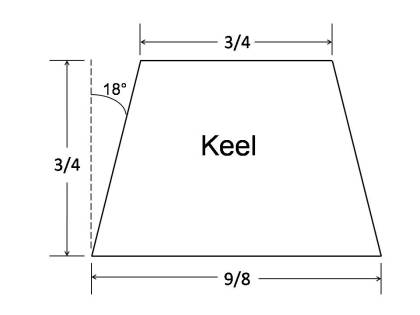

Keel – The Bob Special had a regular (tapered) keel installed. Use a piece of hardwood (the original was ash) and taper each end to 3/8” wide. The overall length is about 13’. It will accept the brass stem-band which is 3/8” wide.

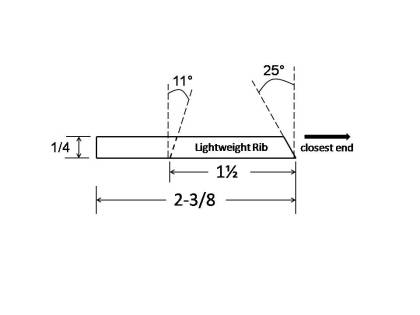

Ribs – The Bobs Special was constructed with so-called “regular” ribs (2-3/8” wide) that were ¼” thick instead of the normal 3/8”. They create a light-weight canoe but are not as robust as the regular ribs. You will probably encounter several broken ribs in your canoe restoration.

The edges of the ribs are chamfered in most Bobs Specials. Replicate the angles found in your canoe. Often, the edge closest to the centre of the canoe has tapered ends (11° chamfer) while the edge closest to one end of the canoe is chamfered about 25°.

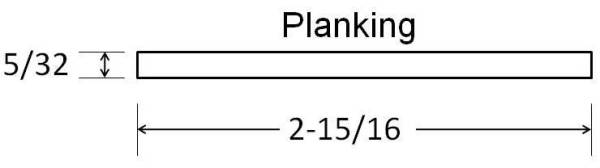

Planking – The planking in Chestnut Canoes was made of either Eastern White Cedar or Western Red Cedar. Although the planks started out at 5/32” thick, you will probably be shaving replacement planks down to match the original planks. Again, this results in a lighter, less robust canoe. You will probably encounter many broken planks in your canoe.

Seats – The seat frames are made of ¾” ash, oak or maple that is 1½” wide. Both seats are suspended under the inwales with 10-24 carriage bolts and held in position with 5/8” hardwood dowel. The rear stern seat dowels are 1¾” long while the front dowels are ¾” long. All of the bow seat dowels are ¾” long. The forward edge of the bow seat is about 51½” from the bow-end of the canoe while the forward edge of the stern seat is about 39½” from the stern-end of the canoe.

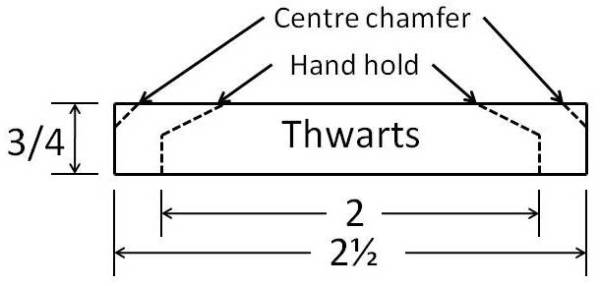

Centre Thwart – The thwart is made of ¾” ash that is 2½” wide. It tapers from the centre to create handle grips on either side that are 2” wide. They were attached directly under the inwales with galvanized steel 10-24 carriage bolts. As with every component in the canoe, I seal the entire thwart with a couple of coats of spar varnish prior to installation and replace the original galvanized steel bolts with silicon bronze bolts.

All of this (and much more) is described in my book – This Old Canoe: How To Restore Your Wood Canvas Canoe.

If you live in Canada, CLICK HERE to buy the book.

If you live in the USA, CLICK HERE to buy the book.

If you live in the UK, CLICK HERE to buy the book.

Si vous habitez en France, CLIQUEZ ICI acheter le livre.

How to Remove Fiberglass from a Wood-Canvas Canoe

March 27, 2019

by Mike Elliott, Kettle River Canoes

email: artisan@canoeshop.ca

For those of you new to this blog and have not heard me on this topic before, let me be as clear as I can be: To anyone thinking about applying fiberglass to a wood-canvas canoe, I say, “DON’T DO IT!” To anyone wanting to remove fiberglass from a wood-canvas canoe, the short answer is: HEAT.

Wood-canvas canoes are a product of a by-gone era; a time before planned obsolescence — when things were built with the long term interests of the consumer in mind. The whole idea of building a canoe with wood and canvas was to have a vessel that lives and breathes. These canoes work in the natural environment and are part of it. They are held together with tacks and screws – no glue. The wood flexes and moves with the water around it. When part of the canoe breaks or rots, it can be repaired or replaced with comparative ease because it is designed to be taken apart and rebuilt. As long as there are people who know how to restore canvas-covered canoes, they will live forever.

It has been about forty years since these canoes were the standard in the marketplace. Not only has the technology of wooden canoe repair faded into obscurity, but the mindset of both manufacturers and consumers has also changed. Synthetic materials are now generally seen as better – easier, tougher and longer lasting. The consumer has been convinced that the new materials can improve that which is outdated or at least maintain it quickly and easily.

When it comes right down to it, wooden canoes and fiberglass just don’t mix. Since the ribs and planking are held together with tacks, they flex and move naturally. Over the years, the tacks tend to work loose and eventually have to be either re-clinched or replaced. Conversely, fiberglass resin is rigid. Once applied, it tends to resist any movement. The combination of a flexible hull and a rigid outside layer results in cracked or delaminated resin. The tacks can also wear against the resin from the inside to the point where they come right through the resin. It can take several months or several decades, but at some point the canoe needs to be repaired and the fiberglass has to come off. It is then that the real problem comes to light. All of that synthetic resin has to be removed. It is a long, painstaking process that usually has you cursing the person that put the stuff on in the first place. The moral of the story is: Avoid applying fiberglass to the hull of a wood-canvas canoe. Learn how to re-canvas the canoe or find a professional to do it for you.

This leads us into the next question: How do you remove fiberglass from a wood-canvas canoe? All you require is a professional-grade heat-gun, a 2” putty knife, a pair of pliers, safety equipment (work gloves, safety glasses and a respirator mask) and lots of patience. The first step is to move the canoe into a well ventilated work space – preferably outdoors. Then start at an edge of the canoe and apply heat to the resin.

At this point it is important to note that fiberglass resins come in two basic types – polyester and epoxy. Polyester resins were the first to be developed. If your canoe had fiberglass applied to it in the 1970’s or earlier, you can bet that polyester resins were used. They tend to become brittle and deteriorate rapidly, so if the fiberglass on your canoe is delaminating it is most likely that you are dealing with a polyester resin. Fortunately, this makes the removal of the fiberglass relatively quick and easy. In many cases, the cloth can be ripped off by hand with very little need for heat. When I say rip, please be gentle. If you get carried away and pull at the fiberglass cloth too rapidly, you could end up tearing sizeable chunks of planking off the canoe as well (I speak from first-hand experience).

Epoxy resins hit the market in a big way in the 1980’s and are the standard today. They are applied by first mixing a hardener with a resin in a two-part formula. What results is a strong, tough plastic that bonds very well to wood. Unfortunately, this means that the removal process is arduous and painstaking.

As mentioned earlier, start at an edge of the canoe and apply heat to the resin. If you are dealing with epoxy resin, you will probably have to apply the heat for several minutes before the cloth begins to respond to your attempts to lift it with the putty knife. At some point, it does let go and the fiberglass cloth can be separated from the canoe. Then move a few centimeters and continue the process. Again, polyester resins let go fairly quickly. You will find that large sheets of cloth come off in fairly short order. I usually grab the cloth with a pair of pliers rather than with my hand. Even with work gloves on, the pliers prevent nasty encounters with heat and/or sharp edges of fiberglass (again, this is the voice of experience talking).

Once all of the fiberglass cloth is removed, return to the canoe hull with the heat gun and a putty knife. Apply heat to any patches of resin still stuck to the wood. Then, scrape the resin off. Be prepared to settle into hours of tedious work. It typically takes 15 to 20 hours to remove the fiberglass cloth and resin from a 16′ canoe.

Once you are back to the bare wood, the restoration is like that of any other wood-canvas canoe. So, enjoy the pleasures of life in the slow lane, stay away from fiberglass and celebrate the fact that you have a wood-canvas canoe.

Many people complement me on the great fiberglass job on my canoes. They are shocked to learn that the canoes are covered with painted canvas.

All of this (and much more) is described in my book – This Old Canoe: How To Restore Your Wood Canvas Canoe.

If you live in Canada, CLICK HERE to buy the book.

If you live in the USA, CLICK HERE to buy the book.

If you live in the UK, CLICK HERE to buy the book.

Si vous habitez en France, CLIQUEZ ICI acheter le livre.

If you have read the book, please post a review on Amazon and/or Goodreads and/or any other review site.

by Mike Elliott, Kettle River Canoes

email: artisan@canoeshop.ca

During the restoration of a wood-canvas canoe, it is rare to have to replace the entire stem in the canoe. However, when faced with the restoration of a canoe which is more than 100 years old, a new stem (or two) is more than likely going to be part of the project.

I restored a 1905 J.H. Rushton Indian Girl canoe. Both stems had extensive rot and one was broken in two places. Rushton made his stems from a solid piece of rock elm. Since this wood is nearly extinct now (thanks to Dutch Elm Disease), I used straight-grained ash 1″ (25mm) thick (at the lumber yard this is referred to as 4/4 ̶ pronounced four-quarters).

The first step is to remove the stems from the canoe. I use both a tack remover and a Japanese concave cutter bonsai tool to remove the fasteners without doing too much damage to the ribs, planks and stems in the canoe.

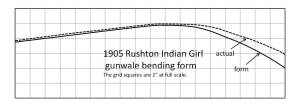

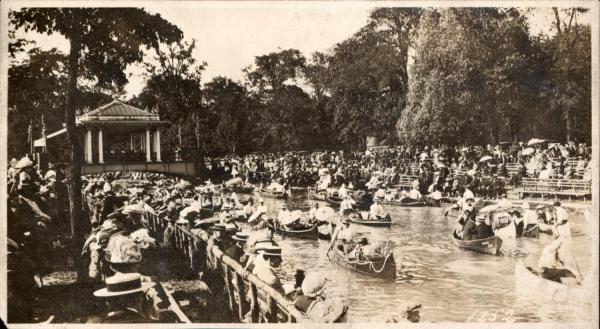

The next step is to create a bending form. Here, I present the dimensions of the bending form required for the Rushton Indian Girl.

It is comprised of three layers of 5/8″ (16mm) plywood. I ask my local building supply centre if they have any damaged sheets of plywood. I can get all of the wood I require for a fraction of the cost of full sheets of plywood. All three piece have the same curve but the centre piece of plywood has a longer base which clamps easily into a work-bench vice.

I start by placing the original stem on one piece of plywood and drawing the inside curve of the stem onto it.

I then keep the stem-top in the same location as the original while rotating the stem until the curve is about 3½” (9cm) greater than the original. The form shape is then drawn onto the plywood and is extended about 6″ (15cm) at both ends to accommodate the clamping system.

The form shape is cut with a saber saw or band saw. The first piece is then used as a template for the other two pieces. Once assembled, the form is sanded more or less square with a belt sander or an angle grinder set up with a 24-grit wood grinding disk. The final form is 1.875″ (48mm) wide.

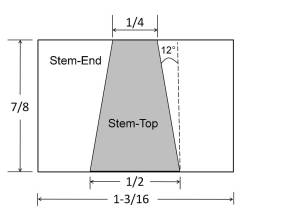

The base-end of the stem is 1.1875″ (30mm) wide and 0.875″ (22mm) thick. I bend a piece of ash which is 1¼” (32mm) wide and 1″ (25mm) thick. This allows me to shape an exact replica of the original.

The clamping system is attached to the bending form with enough space for the new wood and a backing strip. The new stem stock is soaked in water for four days, steamed for 60 minutes and bent onto the form where it remains for at least a week. When removed from the form, the new wood will spring-back slightly and ought to come to the same shape as the original (or close enough).

The original stem is much more than just the curve in its profile. It is tapered at the stem-end, angled to accept planking and notched to accept ribs. Draw the rough dimensions and contours onto the new stem (first with a pencil and then with a permanent ink pen).

Use a Japanese cross-cut saw or a dovetail saw to cut the sides of the rib notches at the correct angles and depths. Use a wood chisel and mallet to remove the bulk of the material in each notch.

Check the dimensions of each notch on the original and use the chisel to shave each new notch to the desired thickness.

Use an angle grinder set up with a 24-grit wood sanding disk to carve the desired angles and tapers into the new stem.

Work slowly and carefully with a random-orbital sander and 60-grit sandpaper (checking dimensions with calipers against the original) until the new stem is an exact replica of the original.

Turn the canoe upside down and use spring clamps to hold the new stem in place while you drill pilot holes for bronze ring nails to attach it to the ribs.

Use a cobblers hammer backed with a clinching iron to drive the ring nails tight.

Turn the canoe right-side up and sight down the centre-line. Position the stem so it is lined up straight down the centre-line and clamp it in place. Pre-drill holes for 16mm brass canoe tacks and attach the new stem to the original planks.

Mark the height of the stem-top against the underside of the inwale-ends.

Use a Japanese cross-cut saw to trim the stem-top to its desired height. I cut it a little long and use a random-orbital sander to achieve a snug fit.

Attach the rest of the planking to complete the job.

The entire restoration process (including stem repairs and replacement) is described in my book – This Old Canoe: How To Restore Your Wood Canvas Canoe.

If you live in Canada, CLICK HERE to buy the book.

If you live in the USA, CLICK HERE to buy the book.

If you live in the UK, CLICK HERE to buy the book.

Si vous habitez en France, CLIQUEZ ICI acheter le livre.

If you have read the book, please post a review on Amazon, Goodreads and/or any other review site.

How to Replace Pocketed Inwales in a 1905 J. H. Rushton Indian Girl Wood-Canvas Canoe

March 19, 2019

by Mike Elliott, Kettle River Canoes

email: artisan@canoeshop.ca

In the early days of wood-canvas canoe construction (late 1800’s until about 1906), builders (primarily in up-state New York and Maine) tried to emulate the birch bark canoes in the region. Like birch bark canoes, they constructed their hulls with cedar ribs and planks. They also emulated the look of the gunwales. The inwales and outwales of birch bark canoes are lashed together and the rib-tops are whittled to wedges which are forced up between the inwales and outwales.

To replicate this look, the builders cut pockets in the inwales into which the rib-tops were fitted and nailed. The outwales were attached (with brass screws) directly to the inwales to create a closed gunwale. This looks beautiful. However, with regular use, water collects in the pockets and creates a moist environment perfect for the growth of the fungi that cause wood rot. Around 1906, all of the builders transitioned to an open gunwale system which allows water to drain quickly from the canoe.

To describe and document the replacement of pocketed inwales, I worked on a 1905 J.H. Rushton Indian Girl canoe. This particular canoe was in pretty rough shape when it arrived in my shop, but I was able to determine the original dimensions of the component parts from salvaged pieces.

Replacing the original inwales is complicated by the fact that the canoe is already built. In 1905, the builder started constructing the canoe by making the inwales first (complete with pockets already cut). He then placed them in the building mould and fit the rib-tops into the pockets. The process of replacing the inwales is the exact opposite. The inwales must be fitted to the canoe. Then the position of each pocket is marked and cut before the inwale is installed.

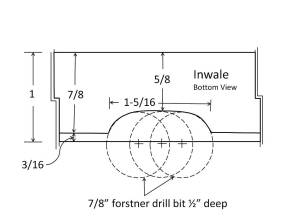

Rushton trimmed his Indian Girl canoes with cherry. The first step is to cut new cherry stock 1″ (25mm) wide and 7/8″ (22mm) high. Then, run the stock through the table saw with the blade angled 8° and 5/8″ (16mm) high to create a rabbet on the outside face ¼” (7mm) from the top surface and 3/16″ (5mm) deep at the top.

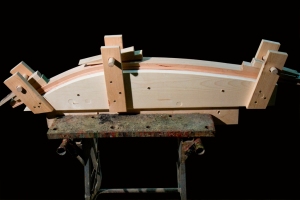

Arrange two 10′ (3 meters) pieces for each inwale and mark the location and orientation of a scarf joint on the four pieces of inwale stock. Soak about 7′ (2 meters) of each piece at the non-scarf joint end for three days. Meanwhile, build a bending form for the ends of the inwale stock.

Heat the ends of the inwale stock with boiling water and bend them onto the form. The bend is not severe, so a backing strip is not required. Allow the wood to dry for about a week before removing them from the form.

Cut a scarf joint angle into the end of one of the pieces (I arbitrarily chose the bow piece) to be used for each inwale. Fit the bow and stern pieces of inwale stock for one side of the canoe into the canoe and match the curve at the ends to the rib-tops in the canoe. Clamp them in place with lots of spring clamps.

Overlap the bow and stern pieces and mark the position of the scarf joint on the stern piece for the inwale.

Cut the scarf joint angle in the stern piece, use polyurethane glue to splice the bow and stern pieces into a full-length inwale and allow it to cure overnight. Perform this sequence on the other side of the canoe to create two inwales.

Once the glue has cured, sand the joint smooth. Then, clamp one of the full-length inwales into the canoe. Use a pencil to mark the position of every rib-top in that inwale. Remove it and do the same thing for the other side. Be sure to label each inwale so you know to which side it belongs.

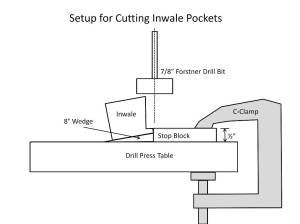

Set up a drill press as illustrated and prepare in-feed and out-feed supports for the inwale.

Cut the pockets on both inwales. You will need help from a second person to guide the inwale through the curves at the ends.

Install one inwale and secure it with clamps at every second rib-top. Pre-drill two ¾” bronze ring-nails in each rib-top.

Use a clinching iron as backing while you drive in the nails. Once the first inwale is fully installed, repeat this process for the second inwale.

Meanwhile, make new cherry decks for each end.

Soak the wood for three days, steam the wood for 60 minutes, bent the decks in a press and allow the wood to dry in the press for a week.

Use a flexible straight edge and a permanent ink pen to mark the inwale tapers at both ends of each inwale.

Use a saber saw to cut the tapers into each inwale-end.

Smooth the tapers with a random orbital sander and 80-grit sandpaper.

Hold the new stem-top (either a new piece spliced into the original stem or, in this case, a completely new stem) against the inwale-ends and mark where the stem-top meets the underside of the new inwale-ends.

Use a Japanese cross-cut saw to cut the stem-top. It is best to cut it a little long initially and sand it gradually (while checking frequently with dry fitting) until the stem-top fits snugly under the inwale-ends. The process of replacing the stems in a 1905 J.H. Rushton Indian Girl will be described in a separate blog (to be posted soon).

Use a ratchet strap to pull the end of the canoe together. Then, dry-fit the deck. Line up a straight edge with the centre-line of the canoe directly above the stem-end at each inwale-end. Then, mark the angle for the inwale joint.

Release the ratchet strap and cut the inwale joint on each inwale-end.

Sand the joint faces smooth with a random orbital sander.

Re-attach the ratchet strap and pull the end of the canoe together again. This time, draw the inwales together until the deck fits properly. Check the inwale joint and make any adjustments to the angle until it fits exactly.

Install the deck and attach it to the inwales with 1½” #8 bronze flat-head wood screws (counter-sunk).

Use a random orbital sander set up with 60-grit sandpaper to sand the deck and inwales until they are perfectly flush.

The entire restoration process (including stem-top repairs, inwale replacement and deck repairs) is described in my book – This Old Canoe: How To Restore Your Wood Canvas Canoe.

If you live in Canada, CLICK HERE to buy the book.

If you live in the USA, CLICK HERE to buy the book.

If you live in the UK, CLICK HERE to buy the book.

Si vous habitez en France, CLIQUEZ ICI acheter le livre.

If you have read the book, please post a review on Amazon, Goodreads and/or any other review site.